Metal Processes Manufacturing Companies

Aluminum Anodizing

EDM

Electroless Nickel Plating

EMI Shielding

Heat Treating

Metal Coating Services

Metal Processes

Metal processing is the foundation of metal production and involves a variety of fabrication methods from stamping and pressing to bending, cutting, and roll forming. Every metal production method includes some form of metal processing that is designed to reshape a piece of flat metal into a configuration to fit a specific application.

A necessary part of the creation of long-lasting products is metal processing, which is used to engineer and create parts and components for easy use and fabrication. The long list of metal processes includes methods that can harden a metal for long lasting use to ones that soften a metal to make it more pliable. Each type of process has been tested and proven capable of producing the exact dimensions necessary for the final product.

Aluminum anodizing is a hardening process used to thicken the oxidized layer of aluminum. One of the reasons that aluminum is such a popular metal is its natural oxidization when exposed to air. The layer of oxide protects the metal surface from corrosion, rust, and wear. Hardening the surface of aluminum by anodization increases its resistance and strengthens it.

An added feature of the anodizing of aluminum is the ability to enhance it with color. The process of anodizing is an electrolytic surface treatment that hardens the metal but also increases its non-conductivity and creates a porous surface for colorization.

A fascinating development in metal processing is electrical discharge machining (EDM) that uses electrical energy to cut, drill, etch, and machine metals. EDM is an extremely accurate machining process that is used by CNC machines to produce complex geometries and precise detailing. The beauty of EDM is its flexibility since it can be used on hard and solid surface but is adaptable to perform delicate and precision machining of soft materials.

There are a wide variety of methods used to protect metals from environmental factors and stress that can cause wear and damage. Some of the processes used to provide protection include painting, coating, and certain powdered materials. A unique form of metal protection is electroless nickel plating that places a layer of nickel alloy on metal using nickel phosphorous or nickel boron, which is deposited on the substrate.

To create the nickel layer, the workpiece is placed in a water solution containing nickel salt and a phosphorus agent. The mixture of the chemicals places an even coating of nickel on the workpiece. The process happens chemically without need for electricity or other form of stimulus.

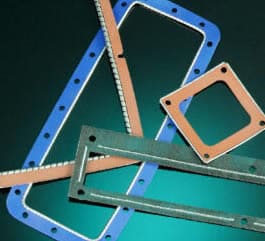

In this age of electronic equipment, devices, and systems, it is important to protect them from interference from external electromagnetic signals that can disrupt their operation or damage their performance. Random electromagnetic interference (EMI) can come from a variety of sources, which can be manmade or a natural phenomenon. The effects of such interference can result in disruption of service, loss of data, or complete system failure.

EMI shielding is a form of mechanical device designed to protect against EMI interference. It is fabricated from metals that are shaped and configured to fit the housings, enclosures, and casings of electronic equipment. The varieties of metal differ according to the needs of the application and the type of protection required.

One of the most common methods for processing metals is heat treatment, which alters the atomic structure of a metal to change its physical, chemical, and mechanical properties. To accomplish the transformation, the metal is put through a series of heating and cooling processes to change the behavioral properties and characteristics.

To enhance the life span of metals and ensure their proper performance, they are treated with a variety of coatings, which are thin layers of a material that are applied to the substrate. There are many varieties of coatings that include powders, paints, and metals. Aside from offering added protection, metal coatings can improve the aesthetic value by tinting and adding texture.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

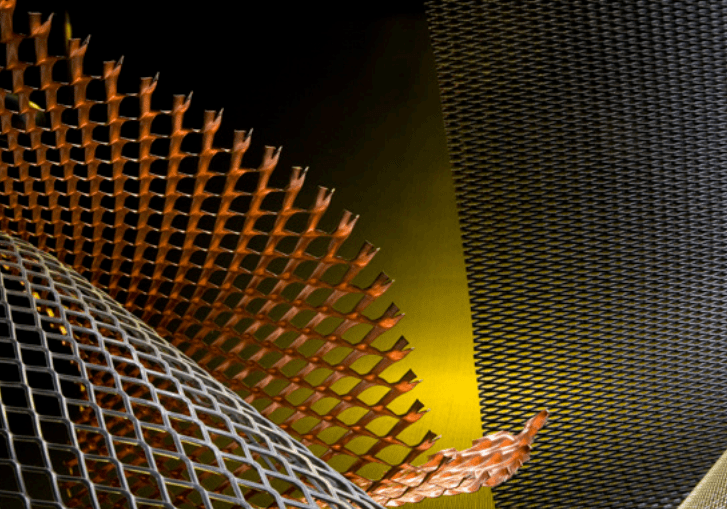

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

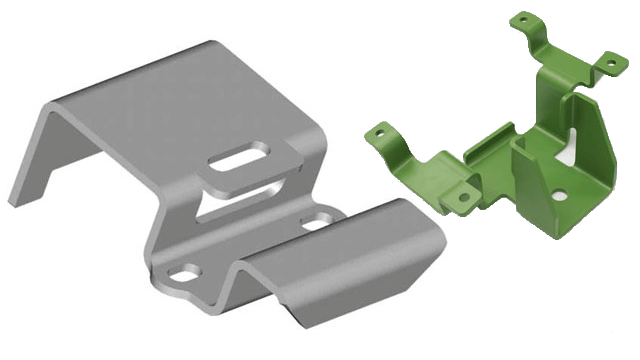

Metal Etching Metal Fabrication

Metal Fabrication Metal Stampings

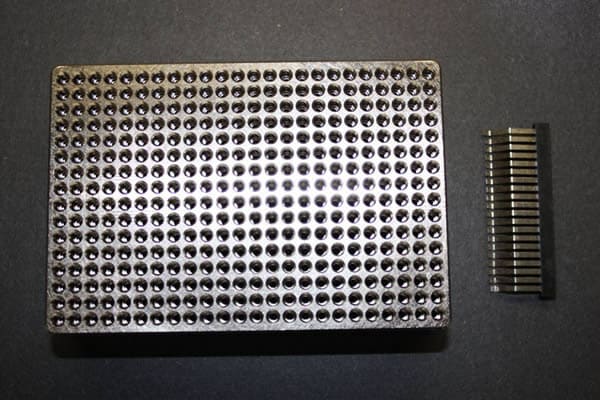

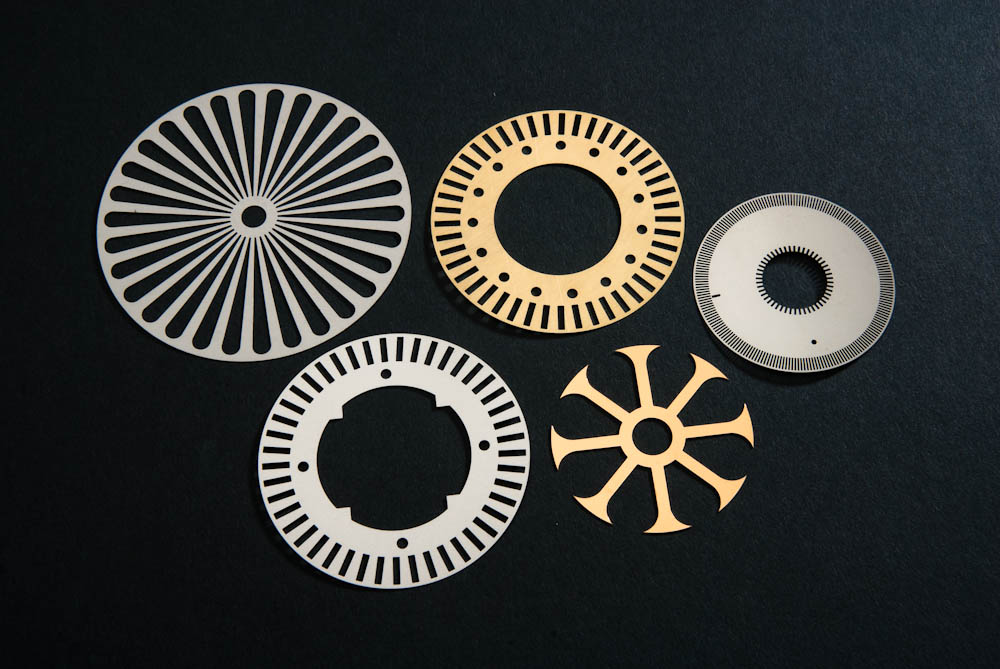

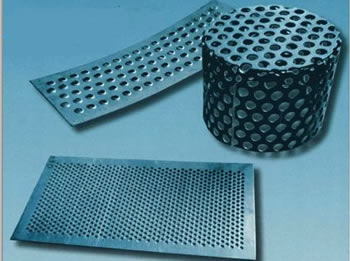

Metal Stampings Perforated Metals

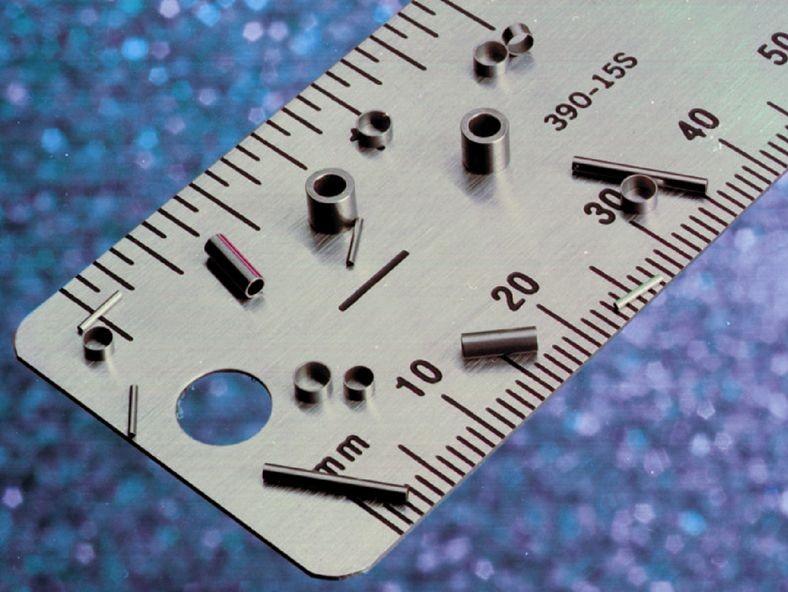

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

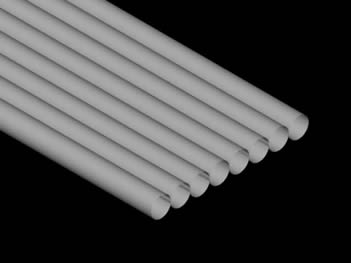

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services