Metal Forming Services Companies

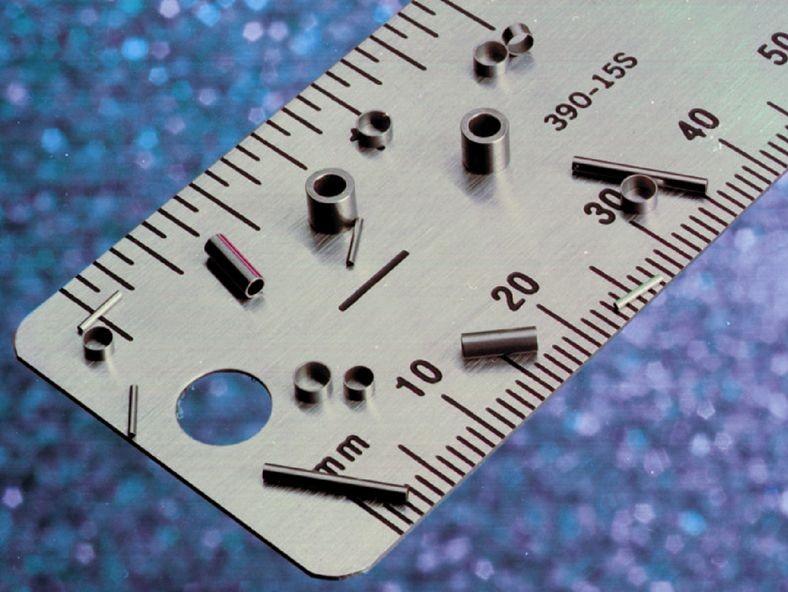

Cold Headed Parts

Die Castings

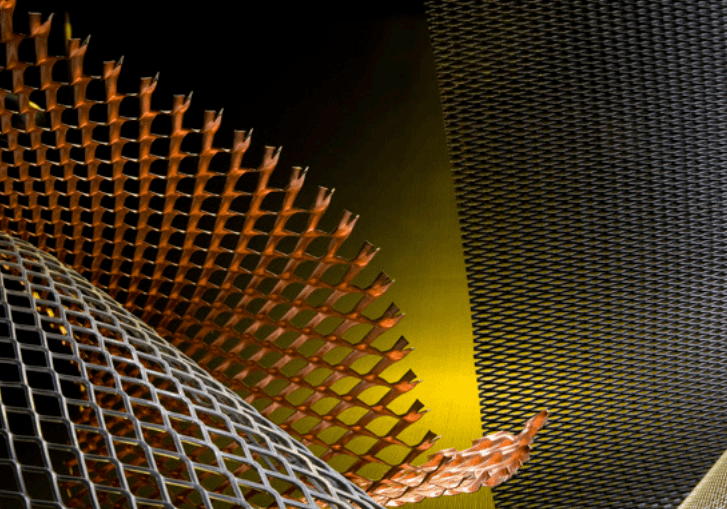

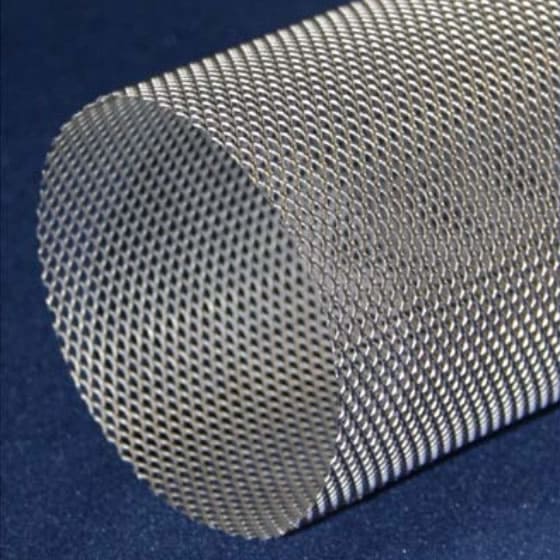

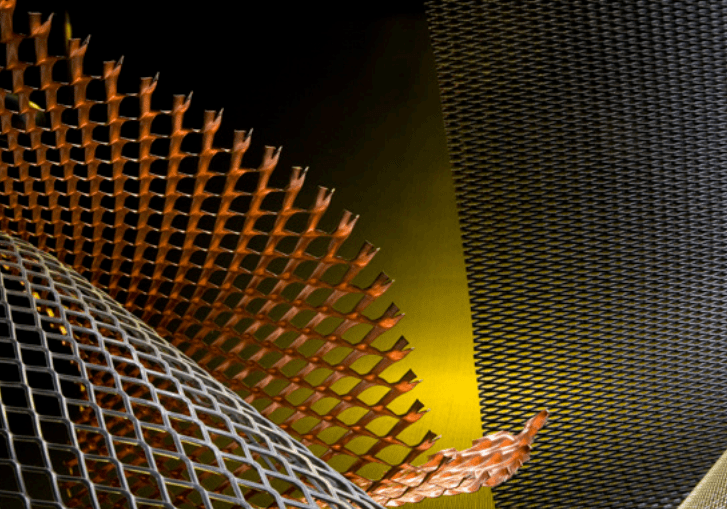

Expanded Metal

Forgings

Grey Iron Castings

Investment Castings

Metal Spinning

Powdered Metal Parts

Roll Forming

Springs

Wire Forms

Wire Mesh

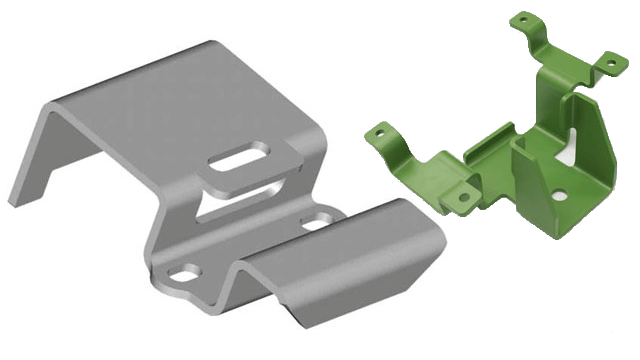

Metal Forming Services

A necessary part of metal production is the forming process that is used to deform metals without removing material or changing its mass. The goal of metal forming is to take a raw piece of metal and shape, configure, and transform it by stressing it through tension, compression, shearing, and pressure.

Since the first industrial revolution, an assortment of metal forming methods have developed. Metal forming begins with a sheet of plain flat metal, which is subjected to forging, rolling, extrusion, drawing, stamping, and an assortment of other methods. Each process is designed to produce a long-lasting metal product.

There are two distinct methods for forming metals, which are hot and cold. The cold process, or cold heading, is completed at room temperature or a little above room temperature. The process of cold heading involves a series of steps that gradually shape the workpiece to the required shape through the use of dies and hammers.

A very popular method for shaping and forming metals is the use of dies, which involves the heating of metals to their melting point and pouring the molten metal into a mold. The majority of die casting is completed using non-ferrous metals such as copper, aluminum, zinc, magnesium, lead, tin, or bronze. The benefit of die casting is the precision of products and parts it produces that extremely close tolerances.

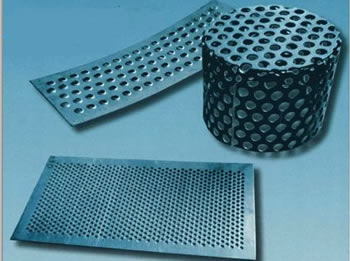

The expanded metal process is a form of cold metal forming where the metal is stretched and pulled. As it is deformed, it is pierced with a blade to create shapes and designs in the metal sheet. The process is less expensive than other methods and can be done on aluminum, various types of steel, and copper. Once the metal has been processed, finishes and coatings can be added for protection or aesthetic value.

One of the oldest forms of metal forming is forging, where a sheet of metal is placed under stress to cause deformation, which changes the grain flow of the metal and forces it to conform to the shape of the forging die. The forging process falls somewhere between cold and hot forging since the metal is not melted but may be heated to make the forging process easier.

Another ancient form of metal forming is grey iron casting, which has been practiced for hundreds of years and should not be confused with forging. Gray iron casting gets its name from the gray color of the metal caused by its graphite content. There are a variety of methods used to produce grey iron castings with sand casting being one of the more common methods.

Investment casting is a process for producing several parts in one casting. The process begins with the creation of a wax model of the part to be formed, which is turned into a mold. The mold is then filled with molten metal to form the final part. The multiple molds are connected by a sprue that is removed after the metal cools.

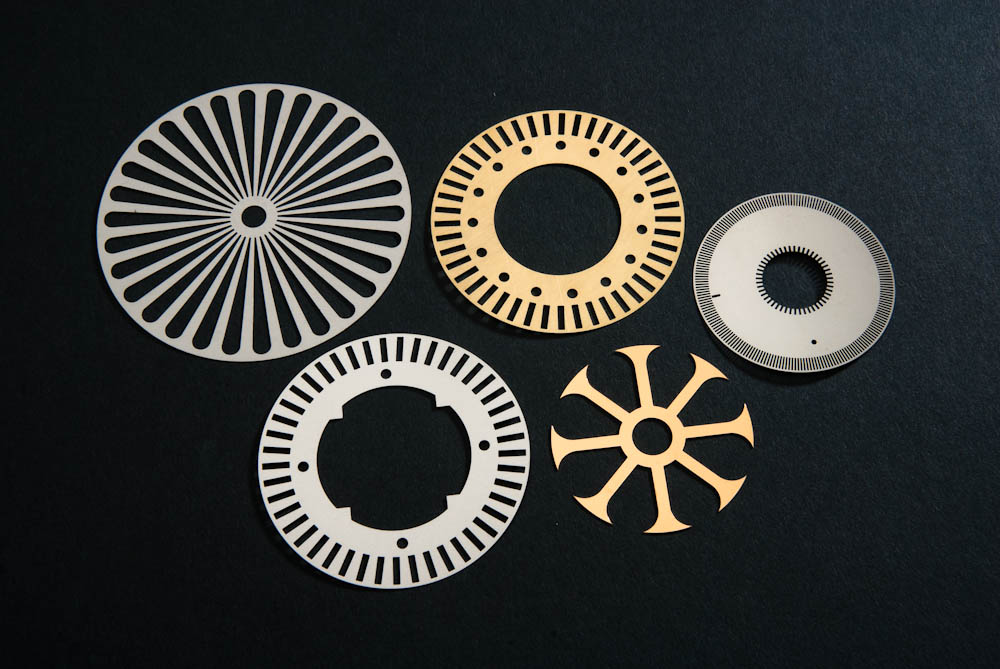

Metal spinning is a cold metal forming process where a flat metal piece is spun at high speed to be shaped and formed. As the metal spins, pressure is applied using a variety of tools called spoons. The methods of applying the pressure vary from a single tool to several depending on the design of the part.

The powder process of metal forming is another of those methods that has been around for centuries. The process involves the use of metal that has been made into a powder. The powder is fed into a die and placed under great pressure. As the pressure increases, particles are forced to interlock to conform to the shape of the die. To harden the part and increase its strength, it is sintered, a process of heating it just below its melting point.

Roll forming is a cold process where a sheet of metal is fed through a series of rollers that gradually reshape the sheet into a uniform shape. Several metals are capable of being rolled formed, which include zinc, brass, steel, and aluminum. It is a low-cost process that produces close tolerance parts.

There are several other types of processes that are used to shape and form metals to produce items such as springs, various wire forms, and wire mesh. The processes used to create these common items are normally cold forming though some methods may heat the metals to make them more pliable.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Metal Stampings

Metal Stampings Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services