Die Cutting Services Companies

Die Cutting Services

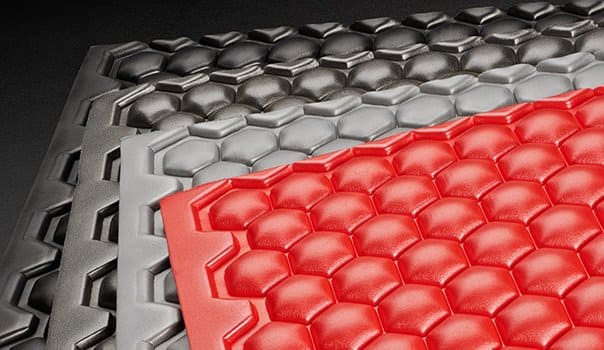

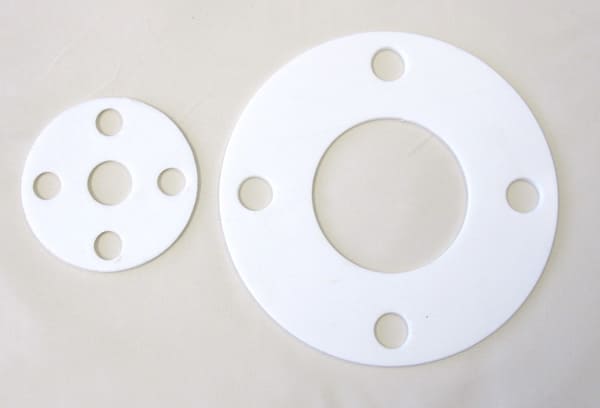

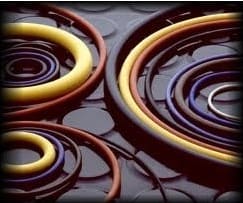

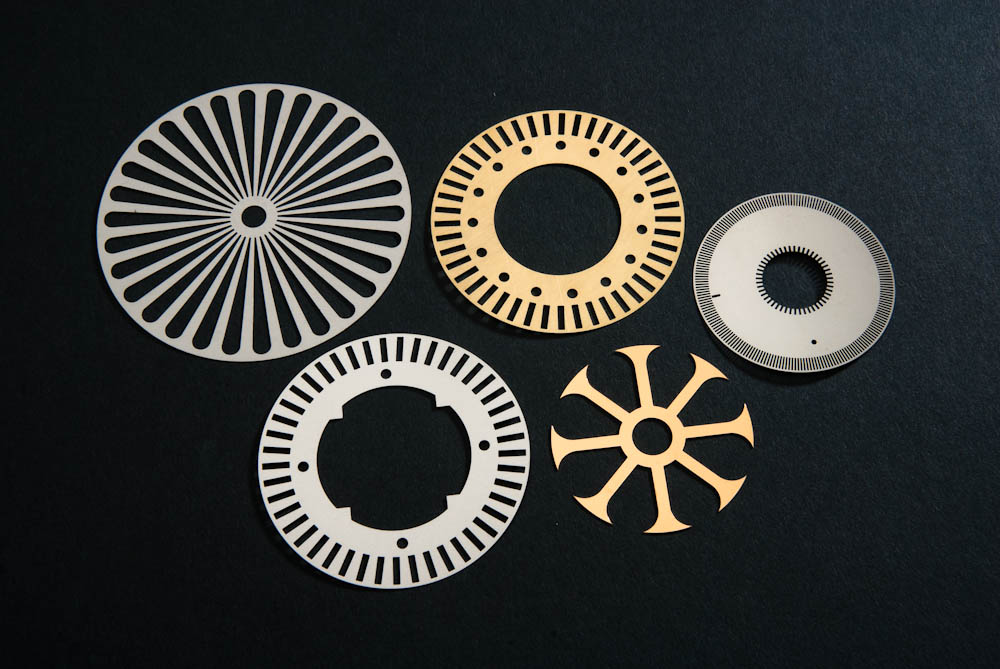

Die cutting is a mass production method of cutting parts, components, and materials efficiently and quickly using specially designed equipment and tools that cut, shear, and shape fabrics such as paper, rubber, fiber, and metals. It is a widely used method for the production of gaskets from neoprene and foam materials.

The term die cutting is a descriptor used for several cutting processes. Each of the different methods fulfills a specific need or configuration. The most common forms of die cutting are flatbed, rotary, and digital. The process chosen for cutting is in accordance with the material to be cut as well as the required efficiency and accuracy.

Flatbed die cutting is the simplest and least complex of the different methods. It is mainly used in production situations where several parts have to be processed in a short period of time. It is selected as a method of cutting for its ease of operation, low cost, versatility, and flexibility. Any type of material can be shaped, configured, or cut using this process.

An exceptional feature of flatbed die presses is their ability to apply extreme pressure on sheet or rolled stock. The factors that determine the use of flatbed die cutting is the type of material, design, and calculated geometries. The process can be used to cut through thin light materials as well as hard thick surfaces.

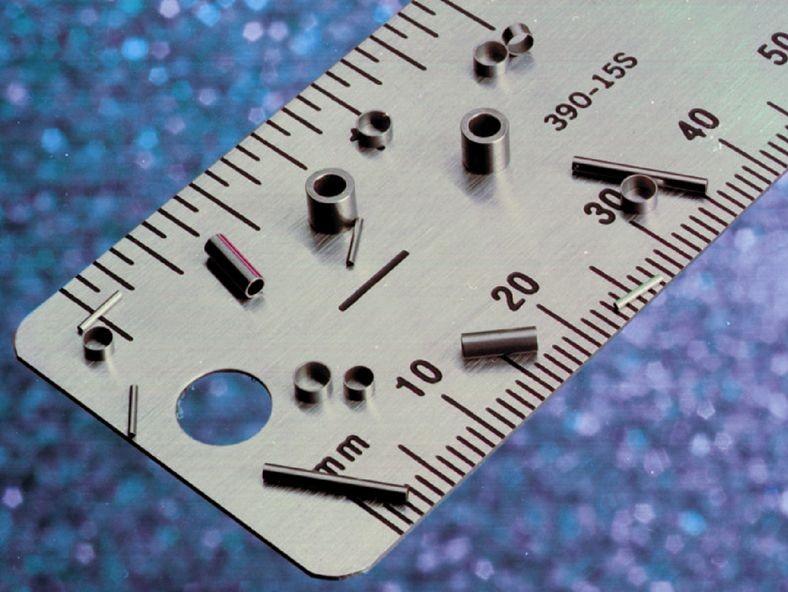

Rotary die cutting is a highly productive method of die cutting that can produce high volumes of parts and products rapidly. It is an exceptionally accurate process that uses dies that are attached to a cylinder in a press. A benefit of rotary die cutting is the multiple layers that can be cut with precision and exactness at very high speeds.

Much like the flatbed process, rotary die cutting is able to have the pressure of its cut set to the type of material to be fabricated with few limitations. Unlike flatbed die cutting, rotary die cutting is limited to web materials.

A popular method of die cutting is digital, which uses CNC programmed lasers, blades, and a variety of tools to cut materials without the use of a die. The process is capable of producing all of the various shapes and designs of the other die cutting methods with more precision at a lower cost.

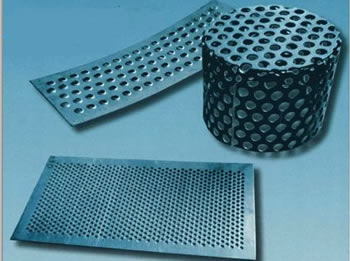

Die cutting is a widely used method of fabrication and shaping due to its ability to be adapted to a variety of applications. Every die cutting machine can produce multiple shapes and forms from an endless number of dies. Dies can be easily changed and customized to fit the material. There are innumerable die cutting operations that vary from bending, coining, embossing, and perforating to name a few.

There are several benefits to using the die cutting process, which include speed, uniformity, and cost. Though die cutting produces parts at a rapid rate, every part is exactly the same from the first to the last. This is one of the main reasons die cutting is used for the fabrication of so many components and parts. Another of its benefits is its ability to be customized and programmed to perform specialized functions to create unique and unusual parts.

Die cutting services developed in the 19th Century to assist shoe manufacturers improve the production of their products. Since its introduction, it has grown to be an essential part of a variety of industries and industrial processes.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

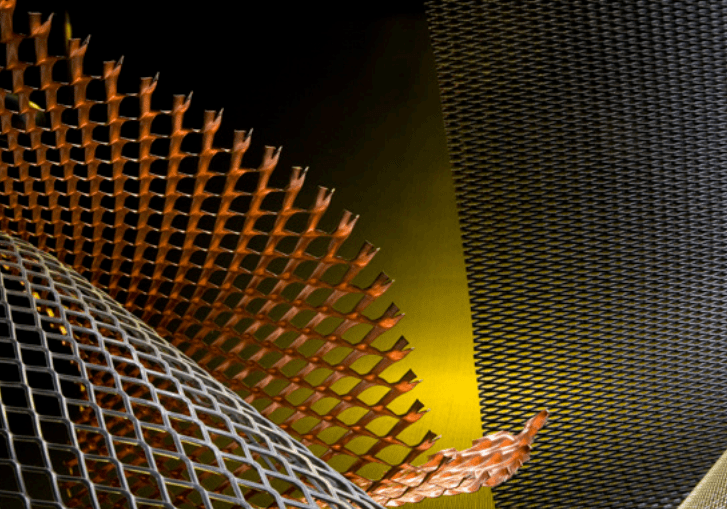

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Metal Stampings

Metal Stampings Perforated Metals

Perforated Metals Screw Machine Products

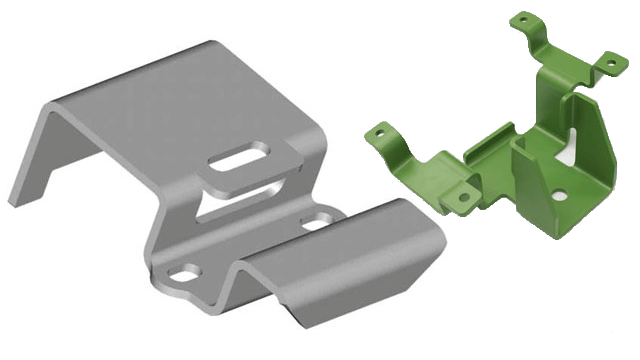

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services