Castings & Forgings

Forgings and Foundries

The term “castings and forgings” refers in general to those metal items made in foundries and forges, respectively. Examples of castings and forgings include: automotive crankshafts, bearing caps, axle carriers, axle tubes, valve bodies, turbine housings, splines, suspension brackets, spring hangers, flanges, gear blanks, and more.

Foundries and forges are both facilities in which whole metal parts are made, though they do so using very different techniques. As implied, foundries are used to make castings, while forges are used to make forgings. However, because the casting and forging products can be so similar, people often incorrectly refer to forges as foundries. Read on to understand the difference in their respective processes.

To make castings, which have mid to high tolerances, manufacturers use closed molds, high pressure, high heat, and molten metal. During casting, manufacturers heat metals until they are molten and then pour them into dies or molds, where they take on that vessel’s shape. Techniques manufacturers in forges use include hot and cold hammering and stamping of solid metal pieces. In other words, castings are made through the manipulation of molten metal, while forgings are made through the application of mechanical and thermal energy on solid metal.

Casting processes can be divided into categories including permanent mold casting, grey iron casting, sand casting, rapid casting, investment casting and die casting. Forging processes can also be subdivided. Some of their categories include hot forging, warm forging, cold forging, drop forging, open-die forging, impression forging, and press forging.

All sorts of metals can be cast and forged. Metals that are typically used in both casting and forging include steel, stainless steel, iron, aluminum, and titanium. Materials used more exclusively in casting include magnesium, copper, tin, and zinc. In addition to regular metal casting, the casting process can also accommodate plaster, plastic resin, concrete, and other chemical curing materials.

Castings and forgings each have their own sets of pros and cons. For example, while forgings are typically limited in size and weight, there is virtually no limit on the potential size or weight of castings. Also, the casting process allows for the creation of much more complex and intricate parts. Also, because the metal is molten during casting, it is much easier for manufacturers to add extra metals to the mix as they create new parts. So, castings are often made from custom alloys. This is rarely the case of forgings. Nevertheless, the process of forging allows manufacturers to create parts with tight grain structures. Because these grain structures give the forgings very high levels of wear resistance and mechanical strength, they are often just as strong as super expensive alloys. Also, forgings avoid several problems faced by castings, including cavities, porosity, shrinkage, and cold pour issues.

It’s hard to say whether castings or forgings are cheaper in the long run, as the processes used to make each have their advantages and disadvantages. For the best advice, we recommend that you consult with an experienced casting and forging sales company or manufacturer.

Aluminum Extrusions

Aluminum Extrusions Broaching

Broaching CNC Machining

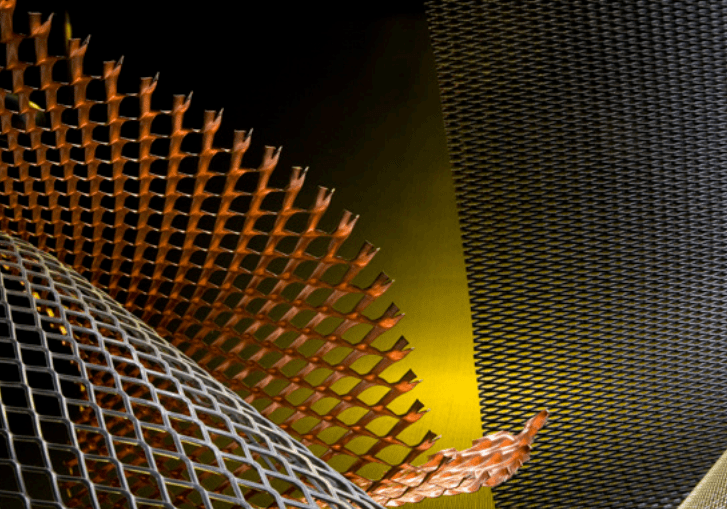

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

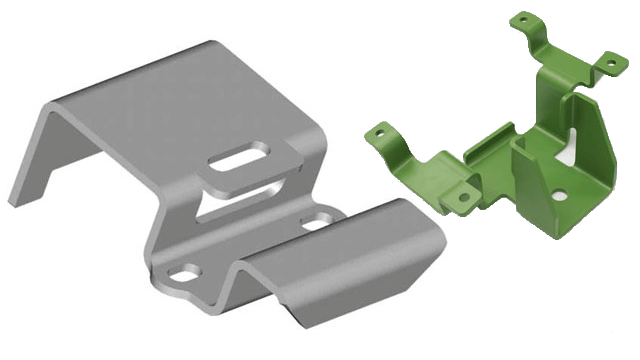

Metal Etching Metal Fabrication

Metal Fabrication Metal Stampings

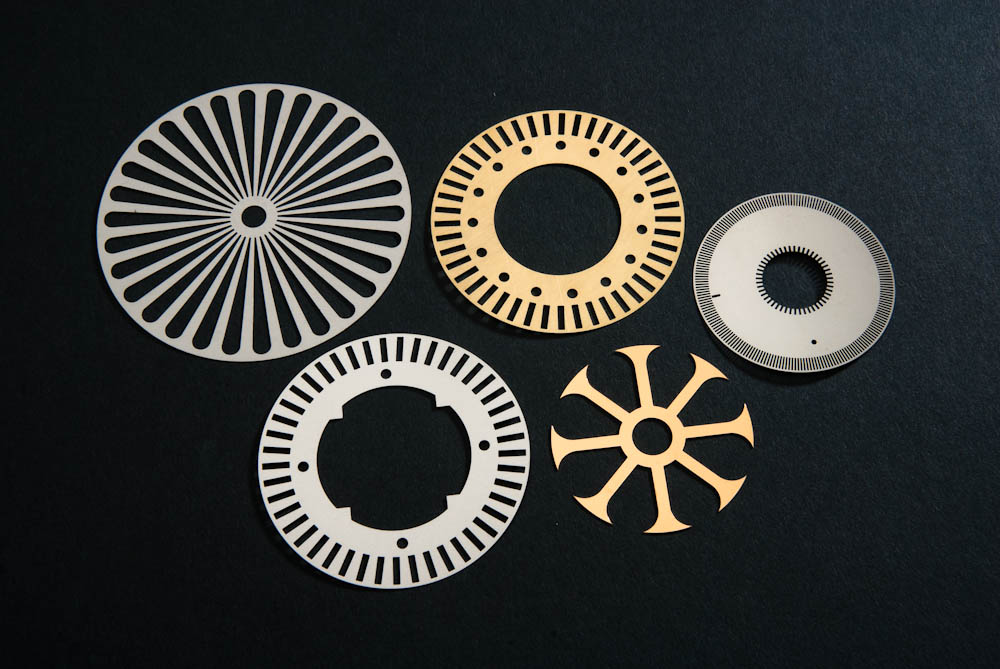

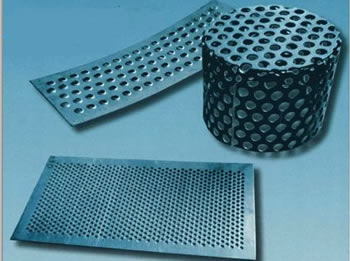

Metal Stampings Perforated Metals

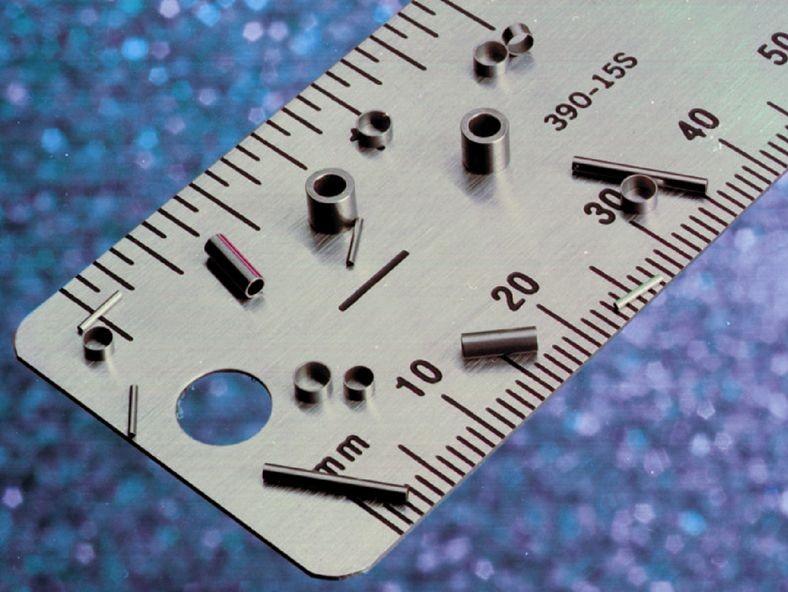

Perforated Metals Screw Machine Products

Screw Machine Products Sheet Metal Fabrication

Sheet Metal Fabrication Steel Service Centers

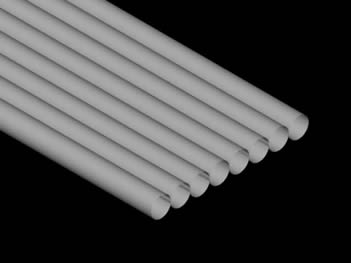

Steel Service Centers Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services